Basic Info.

Model NO.

CE650-7

Size

Large-Scale

Certification

ISO9001: 2000

Condition

New

Color

Orange

Function

Mining

Machine Weight

65t

Diesel Engine

M11-C330

Power /Speed

298/1800

Fuel Tank Capacity

726L

Swing Type

Independenceopen Type

Operating Style

Pilot Control

Swing Speed

6.0r/Min

Travel Speed

3.0km/H

Transport Package

in Bulk

Specification

SGS

Trademark

kudat

Origin

China

Production Capacity

500PCS/Year

Product Description

Main technical characteristic of hydraulic excavator CE650- 7

Main Technology Data of Hydraulic Excavator CE650- 7

Main Components of Hydraulic Excavator CE650- 7

Application of hydraulic excavator CE650- 7

Detailed Images

After-sales Service Warranty

Kudat grants our clients a twelve-month-period or 1500-hours warranty for any machine purchased from us. During the warranty period, in case the defect of material or workmanship has occurred with spare parts in normal operation. The defective part will be repaired or replaced free of charge at our discretion.

Spare Parts

Kudat is dedicated to provide our clients with genuine spare parts with the highest quality, exact fitness and appropriate function. With our global distributor network, you are guaranteed with fast deliveries and services, wherever you are. Please submit your spare parts request to us, and list products name, model, equipment serial number, description of required parts. We guarantee that your request will be handled quickly and appropriately.

Installation & Maintenance

Kudat is able to provide you with the overall installation of complicated machinery and equipment, for example--crawler crane,concrete batching plant, crushing machines etc.,allowing you to start the normal operation of cranes immediately. After installation, we will make inspection of the whole machine, operate equipment, and provide you with testing data reports of installation and operation.

Training

Kudat offer perfect facilities and comfortable environment and can provide training service to different users. The training sessions include product training, operation training, maintenance know-how, technical know-how training, standards, laws and regulations training and other trainings, all of which are tailored to fulfill your individual needs. Training programs can be conducted in our factory field, or at the client's site.

Technical Advice

Kudat can also help clients coordinate with trained service personnel to provide you detailed and extensive knowledge about your specific machine. With our technical advices, your machine service life can be significantly prolonged and sustained with high capacity.

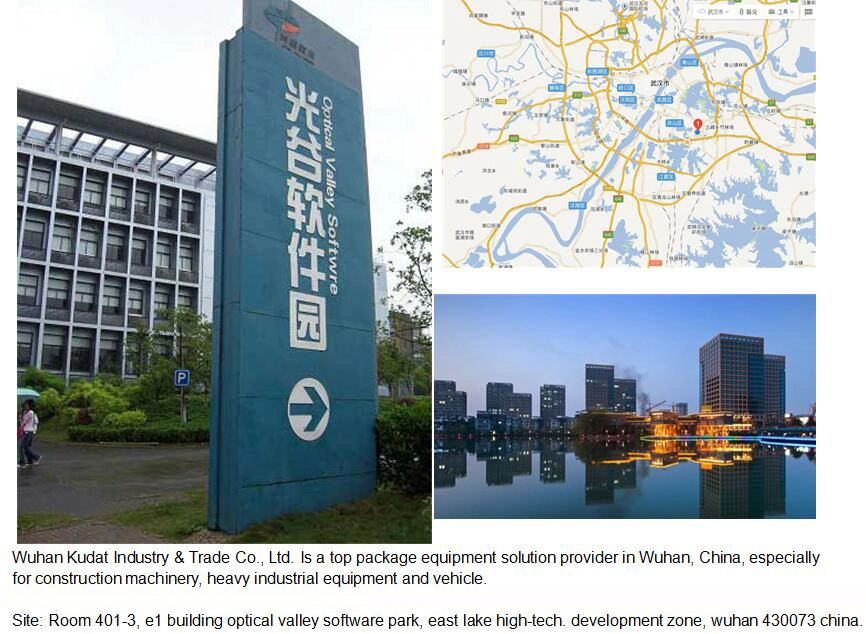

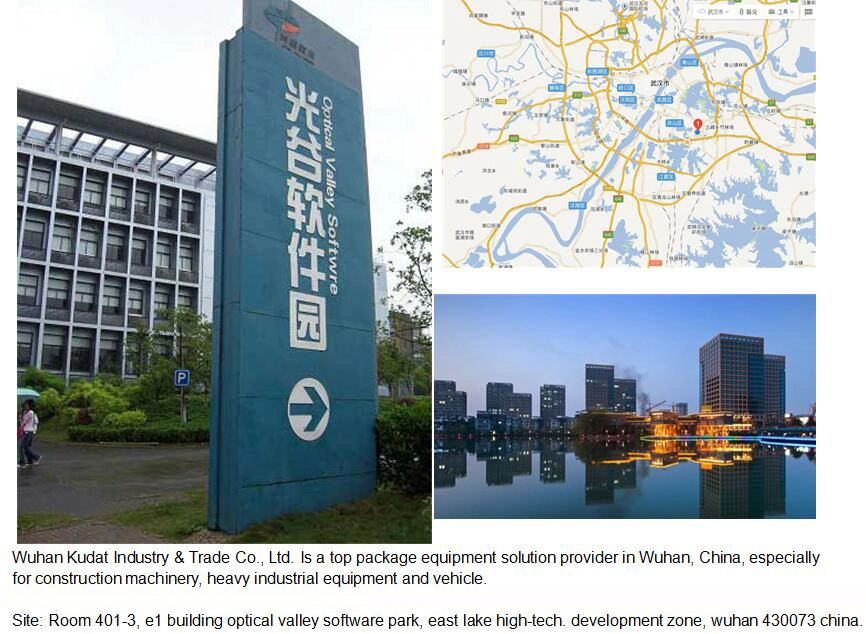

Company Overview

| ○ Turbo-charged after-cooled diesel engine: environment protecting, power saving, its satisfied the emission of Europe Standard Grade.II ○ Control with constant power of single pump, crossover power of two pumps for reasonably distributing and using the power ○ Starting with zero displacement so as to reduce the moment of resistance at starting ○ T echnique with pressure cut to protect hydraulic system and reduce the system heat ○Secondary overloading for swing and normal closed brake for swing and travel ensure smoothly brake ○Integrated oil& water cooler with compact conformation ○ The working attachment realized automatic level crowding with bucket to increase the bucket filling factor ○Attachment designed by CAD, case shape and casting-welding structure realizing the high strength ○Automatic central lubricating system to save daily lubrication ○Multi-function meters show automatic illumination and detection of the various pressure ,temperature and oil level to have sound-light alarm○Better reliability with Parker hose &seals and Trelleborg cylinder seals ○The Technique with disassembled undercarriage which is advanced to transport the machine quickly ○Cab is provided with large tri-dimensional ventilation, fresh air circulation, large capacity air condition without fluorine ○The operator's cab with the wide vision field and the streamlined appearance, matching the decoration and function with human nature, and offering the working environment in a car. |

Main Technology Data of Hydraulic Excavator CE650- 7

| No. | Item | Unit | Date | ||

| Face shovel | Backhoe | ||||

| 1 | Machine weight | t | 65 | 63 | |

| 2 | Bucket capacity | Standard | m 3 | 4.0 | 3.0 |

| Range | m 3 | 3.5~5.0 | 2.7~4.0 | ||

| 3 | Diesel engine | Model | M11-C330 | ||

| Power /Speed | kW/rpm | 246/2100 | |||

| Fuel tank Capacity | L | 726 | |||

| 4 | Hydraulic system | Type | Crossing power variable system with two pumps and two loops | ||

| Max. pressure of main oil circuit | MPa | 30 | |||

| Max. flow of main oil circuit | L/min | 2×400 | |||

| Operating style | Pilot control | ||||

| Hydraulic oil tank capacity | L | 650 | |||

| 5 | Performance | Swing speed | r/min | 6.0 | |

| Travel speed | km/h | 3.0 | |||

| Max. pulling force | KN | 460 | |||

| Gradeability | % | 70 | |||

| Ground pressure | MPa | 0.095 | |||

| Circulating time of operation | s | 24 | |||

| 6 | Working date | Boom length | mm | 4200 | 7100 |

| Stick length | mm | 2800 | 3000 | ||

| Max. digging radius | mm | 9061 | 11950 | ||

| Max. digging depth | mm | 3200 | 7704 | ||

| Max. digging height | mm | 9521 | 10542 | ||

| Max. unloading height | mm | 7911 | 7158 | ||

| Max. digging force of stick | KN | 174 | 174 | ||

| Max. breakout force of bucket | KN | 214 | 214 | ||

Main Components of Hydraulic Excavator CE650- 7

| No. | Component | Type | Manufacturer |

| 1.1 | Diesel engine | M11-C330 | Cummins/ America |

| 2 | Main pump | A11VO190 | Rexroth /Germany |

| 3 | Main Valve | 8M8 | Rexroth /Germany |

| 4 | Double join valves | MO/2MO | Rexroth /Germany |

| 5 | Swing motor | A2FE125 | Rexroth /Germany |

| 6 | Swing reduction gear | GTB80 | Rexroth /Germany |

| 7 | Travel motor | A2FE125 | Rexroth /Germany |

| 8 | Travel reduction gear | GFT110 | Rexroth /Germany |

| 9 | Armrest pilot valve | 4TH6E | Rexroth /Germany |

| 10 | Foot pedal pilot valve | 2TH6R | Rexroth /Germany |

| 11 | Logical valve | 026710 | Rexroth /Germany |

| 12 | Solenoid valve | 4WE | Rexroth /Germany |

| 13 | Driver's seat | DS-85H | Grammer |

| 14 | Hydraulic hose + System seal | Parker/ America | |

| 15 | Cylinder seal | Trelleborg/ America | |

| 16 | Automatic lubricating system | BEKA/Germany or LINCOLN/America | |

| 17 | Track assembly | ITM or Berco/ Italy | |

| 18 | Air-condition system | Wuhan Jindong /China |

Application of hydraulic excavator CE650- 7

| The hydraulic excavator CE650-6, which are based on design platform of the international cooperation and global purchasing of components, adopt the latest technology in the world to meet customer's desire for best performance. Bonny machines have a streamlined appearance which are accepted by international customers, perfect performance, powerful digging force, high productivity and loading efficiency at low operation cost, more availability and long operation life. The powerful earth-moving excavators are applicable to the task of digging of soil grade 1-3, and loading of exploded rocks, such as road construction, municipal project, water power plant, handling of slag, etc.; The powerful mining excavators are suitable for different mines such as non-ferrous metal mine, building material mine, phosphate ore, strip mine and other stripping &loading operation in water power plant. |

Detailed Images

After-sales Service Warranty

Kudat grants our clients a twelve-month-period or 1500-hours warranty for any machine purchased from us. During the warranty period, in case the defect of material or workmanship has occurred with spare parts in normal operation. The defective part will be repaired or replaced free of charge at our discretion.

Spare Parts

Kudat is dedicated to provide our clients with genuine spare parts with the highest quality, exact fitness and appropriate function. With our global distributor network, you are guaranteed with fast deliveries and services, wherever you are. Please submit your spare parts request to us, and list products name, model, equipment serial number, description of required parts. We guarantee that your request will be handled quickly and appropriately.

Installation & Maintenance

Kudat is able to provide you with the overall installation of complicated machinery and equipment, for example--crawler crane,concrete batching plant, crushing machines etc.,allowing you to start the normal operation of cranes immediately. After installation, we will make inspection of the whole machine, operate equipment, and provide you with testing data reports of installation and operation.

Training

Kudat offer perfect facilities and comfortable environment and can provide training service to different users. The training sessions include product training, operation training, maintenance know-how, technical know-how training, standards, laws and regulations training and other trainings, all of which are tailored to fulfill your individual needs. Training programs can be conducted in our factory field, or at the client's site.

Technical Advice

Kudat can also help clients coordinate with trained service personnel to provide you detailed and extensive knowledge about your specific machine. With our technical advices, your machine service life can be significantly prolonged and sustained with high capacity.

Company Overview